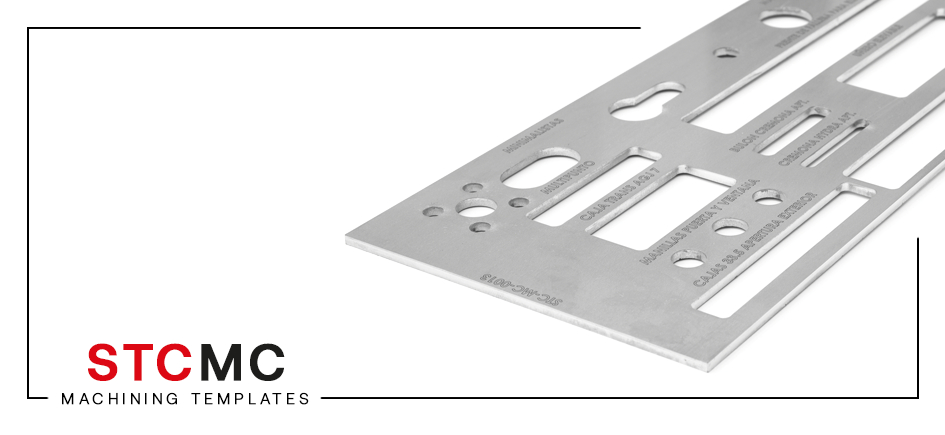

STAC offers all aluminium workshops copying templates that give direct access to multiple machining dimensions of the various hardware ranges.

The following steps in the development of machining templates have been followed by the R&D department:

DIRECT MACHINING

Traditional machining solutions require multiple, tedious manual operations to transfer machining measurements to milling machines. By using templates in aluminium copiers, machining is done directly via measuring feelers.

TIME REDUCTION

The accumulation of documents and information means that in the long run the control of records is lost, directly decreasing effectiveness of the tasks. The copying templates ensure that workshops have greater control, organization and classification of information, allowing them to optimize their processes, better time management, full access to information and, above all, a reduction in information consultation time.

STOCK REDUCTION

A single copying template allows access to different machining measurements, thus ensuring a reduction in stock, avoiding loss of information and minimizing possible errors in workshops where several operators can perform machining operations at the same time, and where errors and time losses are common when locating and managing information.

SOLUTION IN REACH OF ALL

The templates have been developed as a competitively priced solution, within the budget of all workshops. These are the best spec and best priced solution on the market.

Choosing STAC products is synonymous with cutting-edge design, optimum performance and reliability, which only market leaders can offer.