23/04/2021 | Products

STAC has enhanced their range of door hardware with the development of a new range of pull handles with a minimalist style, thus widening their product range and increasing the added-value of their closure systems.

23/04/2021 | Products, Products

At STAC we have a policy of constantly updating and improving our products and so we present our new CLX hinge. With just one product code, the hinges can be mounted on both left and right openings.

23/04/2021 | Products, Products

The trend in architecture and design for pure, simple spaces and objects has meant that closure systems have had to evolve in this direction, offering systems with ever larger fenestrations and doors / windows to make the light the leading element. This has meant that accessories have been reduced to the bare essentials.

23/04/2021 | Products

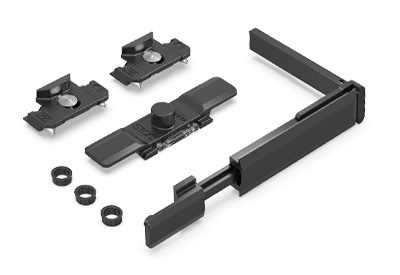

STAC’s commitment to research, development and innovation, we are proud to present a new update in our tilt &turn window hardware – the new supplementary corner drive for Euro Groove profiles. This product offers intuitive installation which allows direct mounting on the window in a simple, straightforward manner, without the need to disassemble the window sash or the hardware.

23/04/2021 | Company, Company, Products

As part of STAC’s exclusive Colour Experience app, STAC & AkzoNobel present the new colour collection for the Interpon® SuperDurable FUTURA 2018 – 2021 range of powder coated accessories.

The FUTURA collection reveals new trends in powder coating and colours. It consists of 50 colours spread over 4 colour palettes with different themes, designed to protect and give colour to symbolic buildings all over the world.

22/04/2021 | Products

Handles with a concealed mechanism that leaves only the handle exposed, leaving nothing unnecessary exposed.

22/04/2021 | Products

STAC presents KAIROX, their new range of stainless steel handles for door and window systems. This new range includes various models allowing you to choose the one that best fits the end user’s requirements.

Las manillas y rosetas, así como los embellecedores de bombillo de las manillas de puerta, están diseñadas en acero inoxidable AISI 304 con el más alto estándar de calidad.

22/04/2021 | Products, Products

With the launch of the new LS200 Lift & Slide hardware system for sliding doors, STAC is pleased to present the new bilingual LS200 documentation (in Spanish and English). Simpler, more intuitive and update this new line of documents incorporates new technology to achieve the best possible end-user experience.

22/04/2021 | Company

As part of STAC’s exclusive Real Colour Experience app, STAC and Axalta Coating Systems are proud to present the new colour collection for the Alesta® SuperDurable ICONICA range of powder coated accessories.