More than sealing profiles, it is understanding insulation as a key part of a whole.

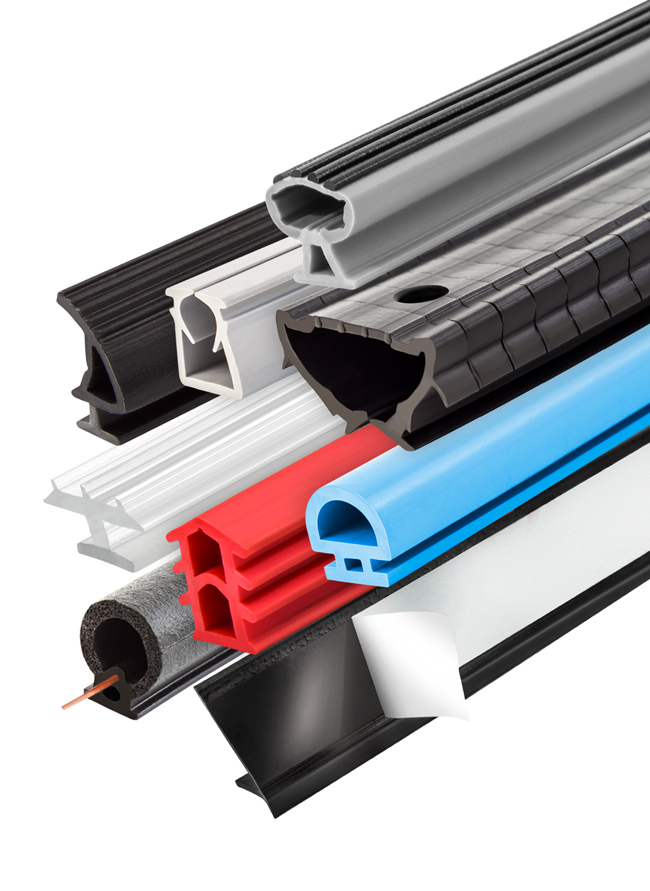

At STAC, we understand each part of an aluminium or PVC window system. Thanks to this, we can design custom sealing gaskets for your product, regardless of their complexity or the material from which they are made.

To do so, we analyse your system to propose innovative solutions in windows and curtain walls, giving your product the perfect insulation and improving the comfort of the building.

We have an advanced die-sinking department that can develop the extrusion die that you need, while also keeping it in perfect conditions for you.

We trust in EPDM as the ideal material for sealing profiles, which is why we are specialised in making dynamic and static profiles in this material.

Thanks to our simulations and prototypes, we can offer you the solution that best adapts to your system, and also to the particular climate in which it is located.

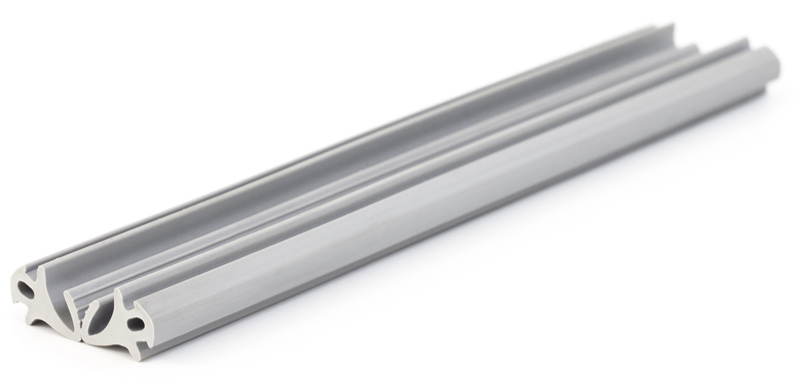

EPDM is a synthetic rubber that is highly resistant to adverse weather conditions.

That is why it is so extensively used in thermal and acoustic insulation applications, particularly in architectural applications for enclosures located in extreme temperatures.

At STAC, we also perform co-extrusion to change the hardness of the EPDM so that it adapts perfectly to your system.

Silicone is frequently used as a thermal and electric insulator, both in industry and in the enclosure sector.

It is most notably used for oven doors and sealing profiles in aluminium profile enclosures.

These profiles are available in a wide range of colours, so they can be used as trims in any application.

Our PVC solutions include rigid and flexible PVC co-extrusions, providing a polymer with unique characteristics.

Thanks to this method we can improve the ageing resistance of PVC, giving it good flexibility and high chemical resistance, even to chlorine.